Slotting Machine Job Work in Kolhapur

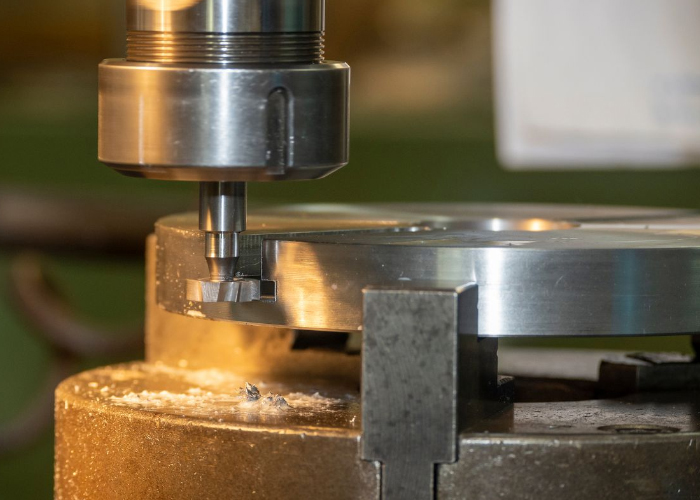

SRN Industries is a leading slotting machine job work and service provider in Kolhapur. Generally, the slotting machine process is used for performing specific machining operations, typically for metals and other hard materials.

Slotting is a process that uses a reciprocating motion to cut grooves, slots, and keyways. This vertical motion allows for precise cutting of accurate designs and shapes, even in hard metals and materials. These machines are powerful and can handle large, heavy materials, irregular shapes, splines, and gears, making them essential in the automotive and manufacturing industries

Various Types of Our Slotting Machine Job Work:

Being a top Slotting Machine Job Work and service provider in kolhapur. We offer slotting machine job work in multiple ways where it is based on specific requirements of the workpiece and the applications, such as:

- Internal Slotting: Internal slotting is used to cut slots or grooves inside hollow parts like gears, pulleys, and cylindrical components. Precise tools, such as single-point cutting tools, create keyways inside gears or hubs, allowing them to fit securely onto shafts for torque transmission. These advanced slotting techniques are commonly applied in the automotive, aerospace, and mechanical industries.

- External Slotting: For improving the mechanism in multiple industries such as construction, automotive and power plant machinery, external slotting is commonly used for improving the overall performance. This slotting method is usually used on the external surface of the workpiece for cutting slots or grooves. These are generally used for shaping the outer contours of mechanical parts such as gear teeth or external slots on shafts.

- Keyway Cutting: Our most common slotting method uses a reciprocating process to cut precise keyways - small slots that hold a key to transfer power between a shaft and another part. This method is widely used in the automotive industry, machinery manufacturing, and industrial equipment. To ensure top-notch accuracy, we use specialized tools like key cutters, broaches, and chisels to get the job done.

- Grooving: For giving a precise alignment to the machines and their equipment, the grooving method is used because of its higher accuracy. The purpose of this method is to create precise grooves or notches on either an internal or external part of the workpiece. We use this method to prove a higher aesthetic appeal in the various equipment such as seals and rings and applied in multiple industries such as hydraulic and pneumatic components and automotive and precision parts manufacturing.

Technical Features of our Slotting Machine Job Work:

We have mentioned below a technical sheet for more information about our Slotting Machine Job Work:

| Features | Internal Slotting | External Slotting | Keyway Cutting | Grooving |

|---|---|---|---|---|

| Purpose | Cutting slots inside components | Cutting slots on external surfaces | Creating keyways for torque transfer | Making grooves or notches |

| Precision | High precision for internal fits | High precision for surface features | High accuracy for mechanical assemblies | Precise dimensions for seals/rings |

| Material Compatibility | Metals, plastics, composites | Metals, plastics | Metals, non-ferrous materials | Metals, plastics |

| Typical Tooling | Specialized slotting cutters | External slotting tools | Keyway cutters | Grooving tools |

| Setup Complexity | Moderate, requires fixturing | Moderate, requires fixturing | Low to moderate | Low to moderate |

| Cycle Time | Generally longer due to internal access | Varies by size | Typically short | Typically short |

| Surface Finish | Smooth internal surfaces | Clean external surfaces | Smooth edges | Good surface finish |

| Production Volume | Suitable for low to medium volume | Suitable for low to medium volume | Often used in medium to high volume | Suitable for low to medium volume |

Important Features of Our Slotting Machine Job Work:

As a former Slotting Machine Job Work and service provider in Kolhapur. We have included new technological machines for improving the workflow of slotting machine job work and giving multiple benefits, such as;

- Increased Productivity: Our slotting machines are built to last and boost productivity, helping us finish tasks faster. They're designed to withstand heavy vibrations during use, ensuring stable operation. With cutting-edge technology and automation, they deliver top-notch accuracy and efficiency.

- Automatic Feed: We utilize slotting machines with automation features like IoT and AI, which increase feed rates, reduce human interaction, and boost productivity. These machines are designed to handle challenging and intricate jobs with ease.

- Customizability and CNC Integration: We use cutting-edge CNC machines for our slotting work, which allow for programmable software to boost accuracy, quality, and efficiency for complex tasks. These machines offer flexibility and speed, enabling operators to easily customize programs, adjust settings, and make quick changes during operations to meet specific needs.

- Safety Features: Safety is our top priority when providing slotting machine job work services. We use machines that meet high safety standards and are equipped with advanced safety features like emergency stop buttons, safety micro-switches, and personal protective gear. Our workers are properly trained to operate the machines safely before starting any task.

Applications of our Slotting Machine Job Work:

Due to multiple types of features and new modern technological innovation we have added in our Slotting Machine Job Work. We use this slotting job work in multiple applications such as:

- Machining of components for medical devices and equipment: We precision-machine parts for medical devices and equipment, ensuring accuracy and reliability.

- Gearbox component and transmission manufacturing: We specialize in machining gearbox and transmission components, enabling smooth power transmission.

- Machining of aircraft engine components: Our expertise extends to machining aircraft engine components, meeting stringent aerospace standards.

- Automotive Industry: We serve the automotive sector by machining various components, including engine blocks and cylinder heads.

- Machining of axle and shaft components: We precision-machine axle and shaft components for heavy machinery and vehicles.

- Machining of satellite and spacecraft components: Our capabilities include machining components for satellite and spacecraft applications, meeting precise specifications.

- Machining of components of power generation and distribution equipment: We machine parts for power generation and distribution equipment, supporting the energy sector.

As a former Slotting Machine Job Work and service provider in Kolhapur, we at SRN Industries are dedicated to improving the complex structure of slotting job work through our slotting machine job work services.

We have included multiple types of new modern machines that are more flexible for working in any type of industry. We offer different types of methods, such as internal slotting, external slotting and others, as per the requirements. Contact us today for more information!